Management System

(wMS)?

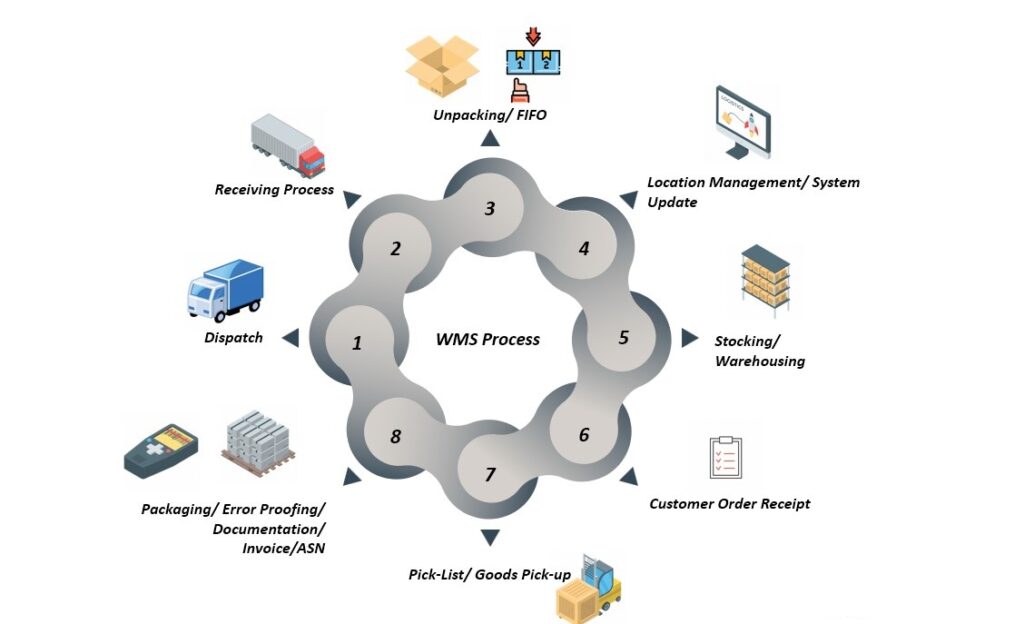

WMS is a software application that helps manage and control

the operations in a warehouse, including tasks such as inventory

management, order fullfillment and tracking of goods.

WMS Overview

WMS is a module that is often overlooked but amongst the most crtitical ones for the smooth operations of any manufacturing facility. The keys reasons include high cost of acquisition, lack of awareness and dependency on manual labor.

We in AAD have developed an affordable, cloud based, interoperable WMS system that can be deployed to work with any ERP or stand-alone system.

WMS software can also be integrated with AAD’s sequencing module to provide a holistic solution(For customer who are shipping (JIT)- Just in Time)

WMS software is mobile device compatible system which can be used for multitude of applications. Our system is capable of integrating with several system including TMS, EDI, error-proofing, GPS, etc.

AAD Benefits

Improved Inventory Accuracy

WMS helps reduce errors in inventory management through real-time tracking and automated data capture technologies. This leads to improved accuracy in stock levels and minimizes the risk of stockouts or overstock situations

Enhanced Efficiency

Automation of routine tasks such as order picking, packing, and shipping leads to increased operational efficiency. WMS optimizes workflows and minimizes manual errors, resulting in faster and more accurate order fulfillment

Optimized Space Utilization

AAD aids in the efficient utilization of warehouse space by providing insights into inventory storage patterns. This can help businesses organize their warehouses more effectively, reducing wasted space and improving overall storage capacity

Increased Productivity

Streamlined processes and reduced manual handling lead to increased productivity among warehouse staff. Automated workflows, guided picking processes, and optimized routes contribute to faster and more efficient operations

Real-Time Visibility

AAD provides real-time visibility into warehouse operations. Managers can track inventory movements, monitor order statuses, and generate reports instantly, enabling informed decision-making and proactive problem-solving

Data Analytics and Reporting

WMS generates detailed reports and analytics, providing insights into warehouse performance, inventory trends, and order history. Businesses can use this data to make informed decisions and continually optimize their operations

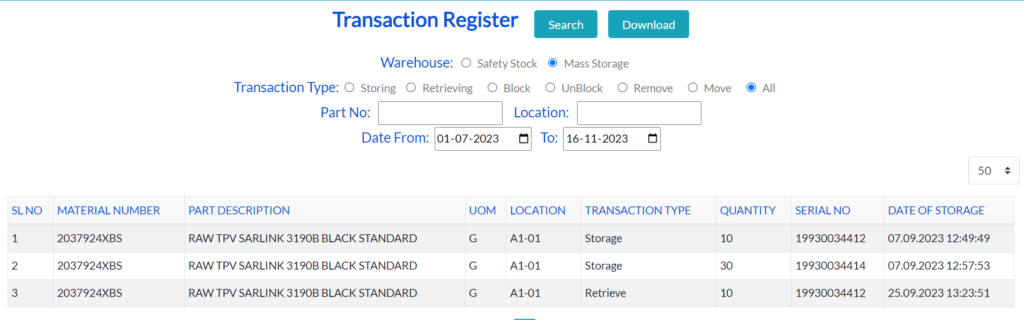

AAD WMS Reports

Real time data on Transaction, FIFO and Stock can be found in WMS application. Detailed reports and analytics, providing insights into warehouse performance, inventory trends, and order history. Businesses can use this data to make informed decisions and continually optimize their operations

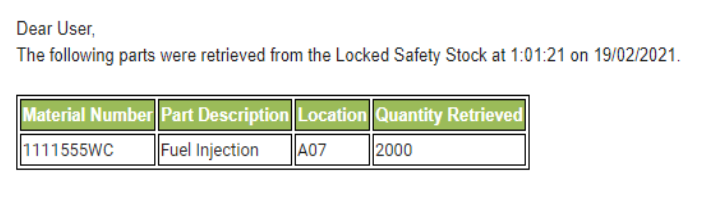

Email Reports are provided for every transactions done in WMS application. An stock alert email will be triggered if stock is below the minimum stock

AAD's WMS Capability

- Receiving, creation of barcode and GRN

- Assigning of location (Static/ Dynamic)

- Automated FIFO

- Material issuance integrated with production planning

- Material Traceability

- Auto integration with Tier II ASNs

- Auto integration with ERP stock accountability

- EDI integration

- Vehicle Status/ GPS tracking

- Receiving, creation of barcode as per customer requirements

- Poke-yoke (viz., Packing standards/ weighing system)

- Scan to verify part number and quantity

- Assigning of location (Static/ Dynamic)

- Automated FIFO, Traceability

- Auto integration with invoicing and auto ASNs

- Auto integration with ERP stock accountability

- ASNs/ EDI/ GPS tracking/ Fleet Management